Anaerobic Biodigester Project

Transforming Food Waste into Clean Energy & Fertilizer for New Canaan

Chomp's containerized biodigester system - delivered ready for installation

Federal Funding Available Through 2032

The Inflation Reduction Act (IRA) provides substantial tax credits for biodigester projects, reducing upfront costs by 30-50%.

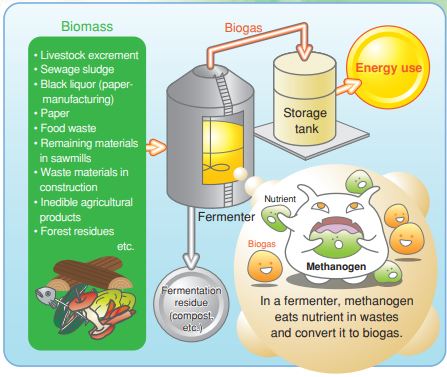

How Anaerobic Digestion Works

Complete biogas production process: from diverse biomass inputs through anaerobic fermentation to renewable energy and organic fertilizer outputs

Collection

Food waste collected from schools, restaurants, and institutions

Digestion

Bacteria break down waste in oxygen-free tanks at 95-100°F for 3-4 weeks

Energy Production

Biogas captured and converted to electricity or renewable natural gas

Fertilizer Output

Nutrient-rich digestate used as organic fertilizer for farms and parks

Environmental Impact

95%+ GHG Reduction

Prevents methane emissions from landfills while generating renewable energy, achieving the highest emissions reduction of any food waste solution.

Equivalent to removing 990 cars from the road

Renewable Energy Generation

Biogas can power municipal buildings, be sold to the grid, or converted to renewable natural gas (RNG) for vehicles.

Enough to power 45 homes annually

Organic Fertilizer Production

Digestate is a nutrient-rich organic fertilizer that can be used on town parks, athletic fields, or sold to local farms.

High-quality organic soil amendment

Cost Analysis

Capital Investment

Annual Operating Economics

Payback Period: 2-4 Years

With federal tax credits, the system pays for itself in 2-4 years through tipping fee savings and energy revenue. Over 20 years, net savings could exceed $2.5 million.

Implementation Timeline

Phase 1: Planning & Design

6-9 months- Feasibility study & site selection

- Engineering design & permitting

- Secure federal tax credits

- Community engagement

Phase 2: Construction

12-18 months- Site preparation & foundation

- Equipment installation

- Electrical & gas connections

- Testing & commissioning

Phase 3: Operations

Ongoing- Staff training & hiring

- Waste collection logistics

- Energy offtake agreements

- Monitoring & optimization

Total Timeline: 2-3 Years

From initial planning to full operations. Starting now positions New Canaan to meet the January 2026 CT compliance deadline and maximize federal tax credit benefits before they phase out.

Proven Success Stories

UC Davis - Chomp Biodigester

UC Davis installed a Chomp biodigester in 2021 to process campus food waste. The system handles 20-30 tons per week, generates renewable natural gas for campus vehicles, and produces organic fertilizer for the campus farm.

Massachusetts Biodigester Network

Massachusetts built extensive biodigester infrastructure to support their 2014 food waste ban. The state achieved 7% total waste reduction - the only state to meet its goals among early adopters.

Ready to Transform New Canaan's Food Waste?

Join New Canaan in building a sustainable future with renewable energy and zero food waste.

Images courtesy of Chomp Inc.